SEALERS

Midway stock a large range of Prime Exposure sealers. Prime Exposure Coloured and Clear Sealers are made using the finest German polymers and blended in Australia using Australian products. This ensures our quality control and processes are second to none. Their colour sealers have been formulated to provide a highly durable coating that is UV stabilised and can be applied to most cement based surfaces. Not only will Prime Exposure colour sealers enhance the look of your concrete, but it will protect your concrete against mould, staining, algae and moss. It also effectively repels dirt, grime and oils, and can provide a safe anti-slip system so you will never have to worry about slipping or losing your footing.

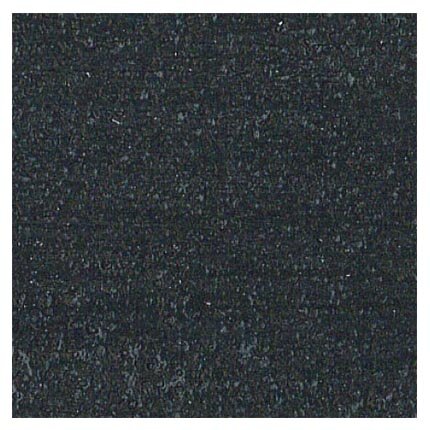

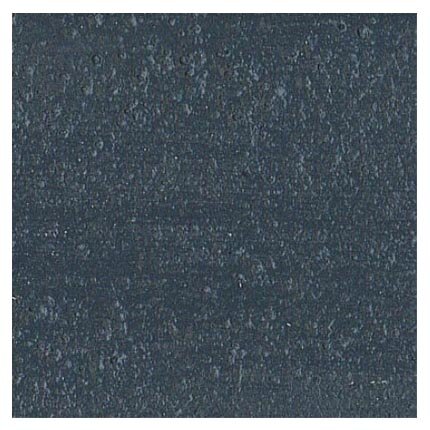

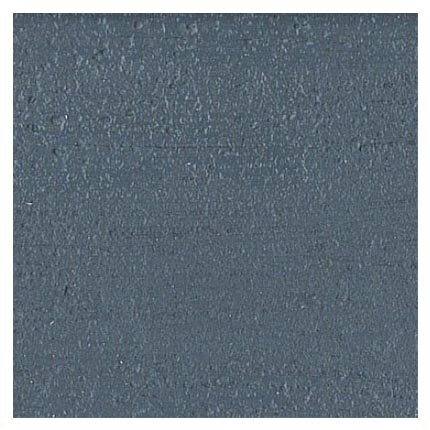

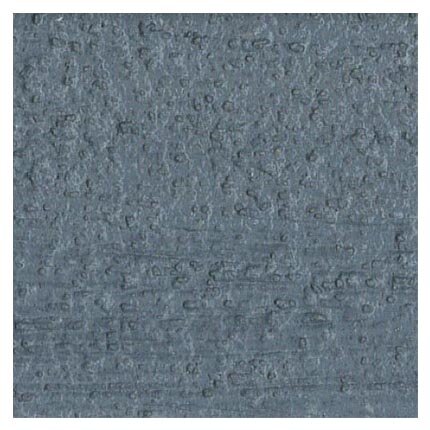

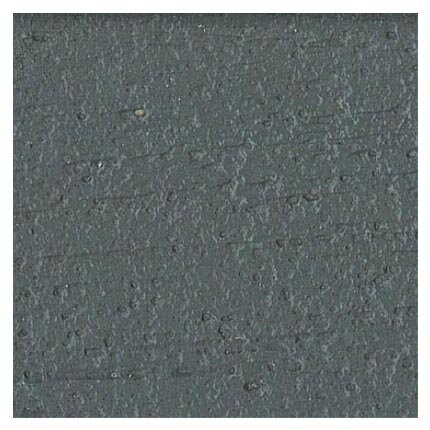

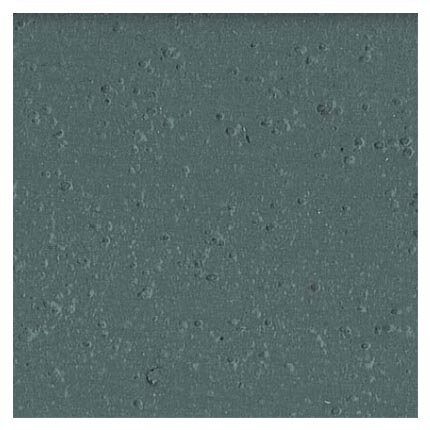

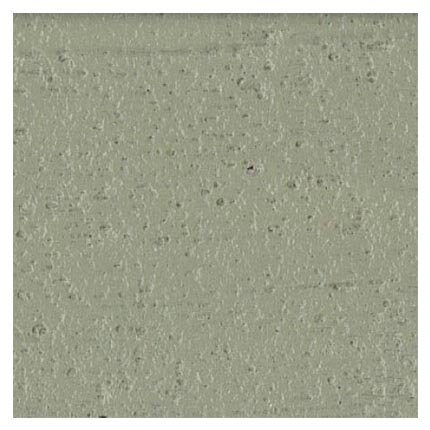

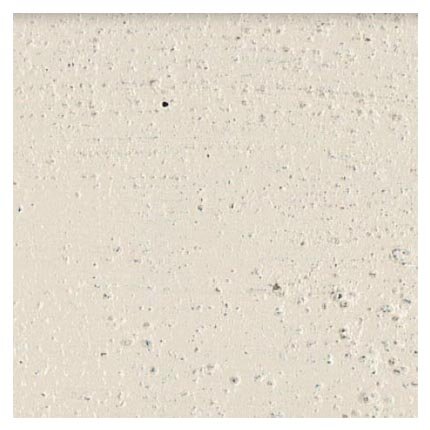

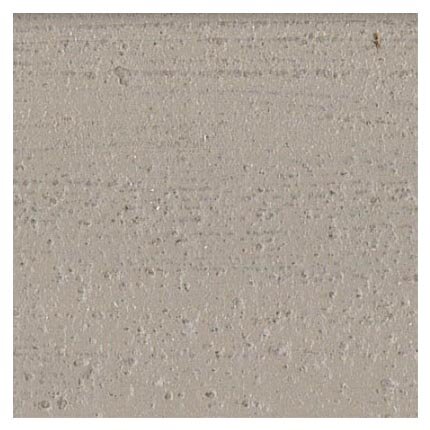

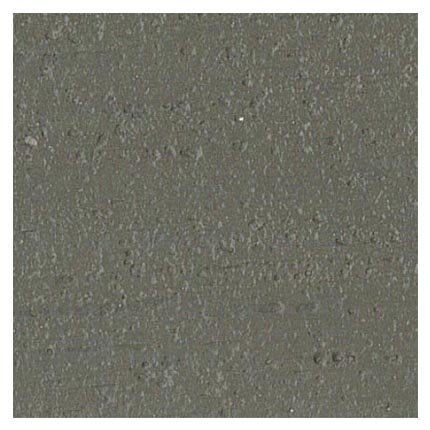

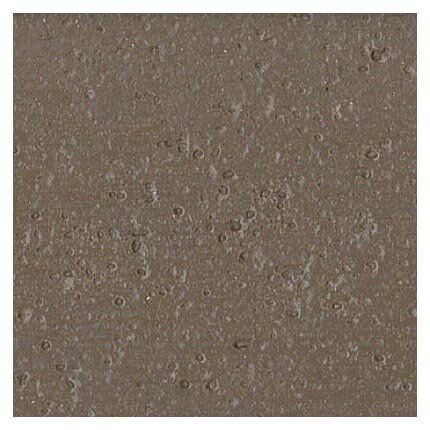

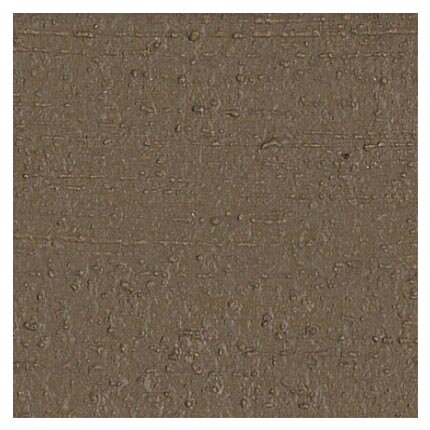

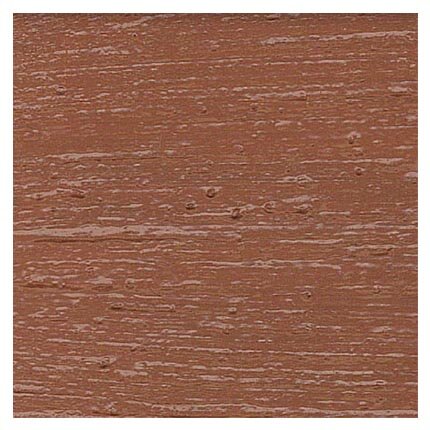

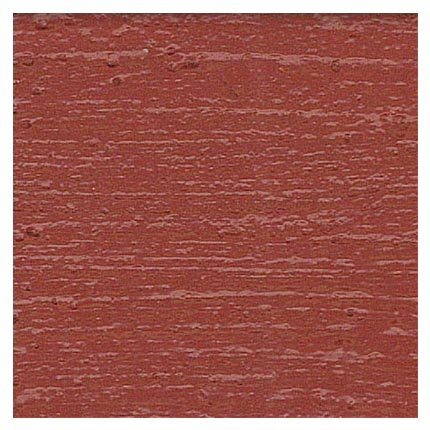

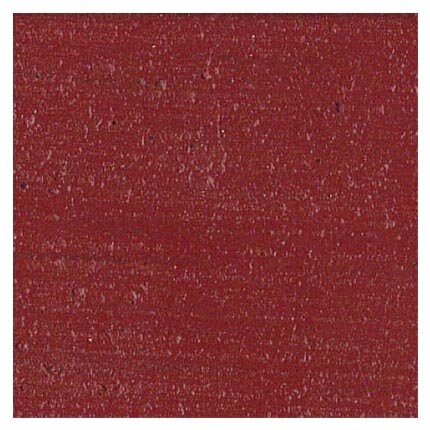

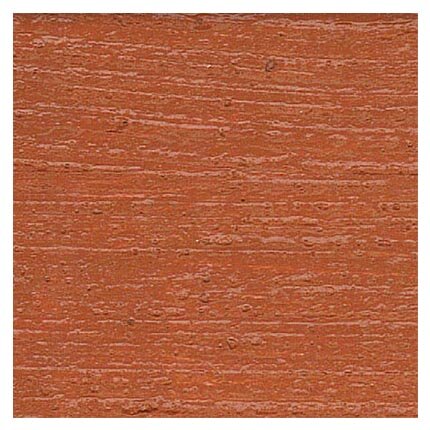

Colour’s shown below are intended as a guide only. Some variation in colour and shading may occur due to job conditions, application technique, chosen texture, finishing practices and the concrete.

+ Surface Preparation

Check the concrete is sufficiently cured, pressure clean the surface (above 2000 psi is preferred) and ensure the surface is free of any grease, oil or any for foreign contaminates.

Remove any loosely bound cement and Efflorescence by acid etching with hydrochloric acid diluted at approximately 9 parts water to one part acid, Do not allow the acid to dry on the surface during this process, thoroughly rinse the surface with fresh water using a garden hose. You must allow the concrete to thoroughly dry prior to sealing!!!!!.

Any moisture will effect the Sealer making it look white and cloudy.

+ Application

For your first coat we recommend 70% Prime Exposure Sealer and 30% Prime Exposure Solvent. This dilution assists to ensure the sealer penetrates the concrete pores binding itself to the concrete. We recommend that you apply the coating by using a roller or broom, ensure that you apply an even coat with no pooling. Allow a minimum of 1 hour before applying your second coat (weather dependant) ideally, waiting for as long as you can between coats for the resin to harden is best.

The second coat requires no thinning down and should be applied at 100% Prime Exposure Sealer.

Please ask your Prime Exposure stockist for Anti Slip beads for any surface that may be a slip hazard.

You can apply Sealer by using a Viton Seal Spray Unit; this process will normally require one diluted and two neat coats.

+ Resealing

For resealing we recommend to follow the above cleaning process and once the surface is totally dry, then apply a coat of Prime Exposure Solvent to reactivate any existing sealer and assist penetration. After the solvent has dried follow the application steps.

+ First Aid

ADVISE THE DOCTOR TO TREAT THE SYMPTOMS IF INHALED: Remove from further exposure. If discomfort persists seek medical assistance. If breathing has stopped, resuscitate immediately.

EYE CONTACT: Flush thoroughly with water for at least 15 minutes. Seek medical assistance.

SKIN CONTACT: Wash contact area with soap and water. Launder contaminated clothing before re-use.

INGESTION: DO NOT induce vomiting because of Solvent aspiration. Milk drinks may soothe. Seek Medical assistance.

Further information refer: S.D.S. or call the POISONS INFORMATION LINE ON 13 1126

+ Please read these important directions before use

SAFETY DIRECTIONS: Please ensure adequate ventilation, avoid breathing vapours by using Australian Standard class p1,p2 particulate respirator ensuring its fitted correctly.

Do not use Prime Exposure Concrete and Paving Sealer whilst smoking or near naked light or flame. Remove all non-canned foods from area if adequate ventilation is not possible during application or drying.

Avoid contact with skin or eyes. Should any irritation occur, please seek Medical advice.

CURING: Approximately 7 days subject to ambient temperatures.

SPILLS AND DISPOSAL: It is important to keep all sealers & Solvents out of sewer and storm water drains. If spills occur, remove or isolate all ignition sources. Contain and absorb spill in dry, inert material such as sand. Collect in sealable containers and dispose of as trade waste in accordance with local authority guidelines.

CLEAN UP: Wash all equipment thoroughly in Prime Exposure solvent and allow to dry.

CAUTION: Sealing concrete, slate, paving or slate impression concrete etc. can cause surface to become slippery, particularly when wet

SAFETY: We recommend the use of Prime Exposure Anti Slip (glass beads) to be applied with the SEALER to “REDUCE” the risk of slipping when wet.

No responsibility can be accepted or any express or implied warranty given where performance of the product is affected by surface preparation, method of application or any other circumstances beyond the company’s control.

STIR WELL BEFORE USE AS THIS PRODUCT CONTAINS LIQUID HYDROCARBONS